Thermoforming Solutions: Quality Across Diverse Industries

Om Raj Tech proudly partners with STM Plastics, a trusted name in advanced thermoforming. STM specializes in custom plastic components, offering both heavy and light-gauge molding for parts up to 8 feet. With a flexible setup of 7 rotary and shuttle/single-station machines, they serve a wide range of industries—from construction and equipment to lawn care, pet products, and waste solutions. Their offerings include reusable packaging, durable covers, and precision parts. Known for quality, speed, and innovation, STM delivers thermoforming solutions that go beyond industry expectations.

Get a Free Quote

Why Partner with Us for Thermoforming?

Our adherence to ISO 9001:2015 standards ensures every phase of production, from tooling design to final quality assurance, follows stringent protocols. Detailed process evaluations and in-line quality checks guarantee parts meet exact dimensional and aesthetic requirements.

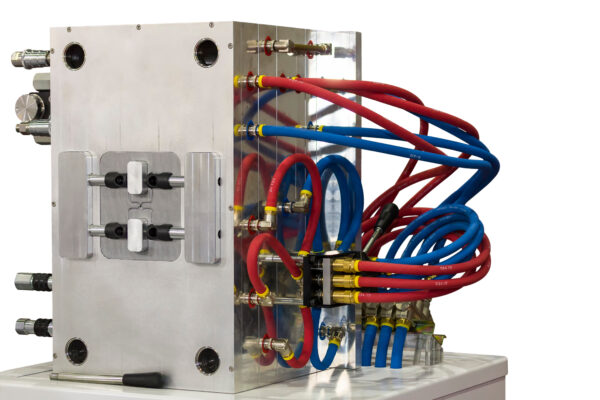

Equipped with versatile, multi-cavity presses (ranging from 110 to 1100 tons), we offer solutions including tool design, insert molding, sub-assembly, and kitting. Our technical expertise supports the development of high-precision tools and bank builds that transition seamlessly from prototype to full production.

Whether you need a limited run or mass production, our flexible process scales to meet your demand—from thousands to millions of units—without compromising quality or consistency.

Precision Thermoforming Solutions for Scalable and Consistent Production

Thermoforming converts thermoplastic sheets into intricate components through controlled heat supplemented by vacuum or pressure. Scalability and consistency are the objectives of this process, where each component is held to stringent standards even in large production runs. Utilizing sophisticated methods—specifically vacuum forming, thick gauge forming, and thin gauge forming—Om Raj Tech offers customized solutions that respond to unique industry needs while minimizing downtime during production.

Our Thermoforming Service

Why Om Raj Tech for Thermoforming?

Om Raj Tech proudly represents STM Plastics as your go-to partner for high-end, high-volume thermoforming solutions. Leveraging state-of-the-art equipment—including 7 rotary machines and 5 shuttle or single station machines—we excel in both heavy and thin-gauge thermoforming, capable of producing parts up to 8 feet in size. Our comprehensive processes span vacuum forming, thick gauge forming, thin gauge forming, and integrated subassembly and kitting services, ensuring technical precision and large-scale production efficiency.

Our sophisticated thermoforming techniques meet the challenging demands of diverse industries, from automotive and industrial equipment to consumer goods and waste management. With full-volume production capability and flexible support in design, development, prototyping, and iterative refinement, we consistently deliver high-performance components with rapid turnaround and unwavering consistency. Whether you need custom packaging for machined parts or durable components for outdoor applications, our solutions are engineered to perform reliably in even the most demanding environments.

Get parts as large as 8ft with Thermoforming!

FAQ's

1. What is thermoforming in plastic manufacturing?

Thermoforming is a manufacturing process where a plastic sheet is heated until pliable, then formed over a mold to create a specific shape. After cooling, the plastic retains the mold’s shape, resulting in durable, lightweight parts used in various industries.

2. What materials are commonly used in thermoforming?

Common materials include ABS, polycarbonate, PETG, PVC, and acrylic. The choice of material depends on the specific application, considering factors like durability, flexibility, heat resistance, and cost-effectiveness.

3. What are the advantages of thermoforming?

Thermoforming offers several benefits, including the ability to create large parts, fast production cycles, cost-effectiveness for small and large runs, and versatility in material use. It’s ideal for creating both simple and complex parts with consistent quality.

4. What industries benefit from thermoformed plastic parts?

Thermoformed plastic parts are used in a wide range of industries, including automotive, medical, packaging, aerospace, consumer goods, and industrial manufacturing. Applications range from automotive panels and medical device housings to food packaging and protective guards.

5. Can thermoforming be used to produce large parts?

Yes, thermoforming is well-suited for producing large parts, such as skylights, industrial guards, and automotive components. Our Manufacturer STM Plastics, has the capability to manufacture parts up to 8 feet in size, meeting the needs of diverse applications.

6. How does thermoforming compare to injection molding?

Thermoforming is generally more cost-effective for large parts and smaller production runs, with faster tooling and setup times. Injection molding, on the other hand, is better suited for high-volume production of smaller, complex parts. The choice between the two depends on the specific project requirements.

7. What are some examples of thermoformed products?

Thermoformed products include automotive body panels, medical trays, food packaging, industrial guards, veterinary heating pads, and consumer items like hats and protective covers. The process is highly versatile, allowing for the creation of both small and large parts.

8. What quality control measures are in place for thermoformed parts?

Our manufacturer STM Plastics, implements a rigorous quality control processes, including material inspection, in-process monitoring, and final part inspection. This ensures that all parts meet safety and industry standards, whether they’re for medical use, industrial applications, or consumer products.

9. Can thermoforming meet specific safety or medical requirements?

Yes, thermoforming can be tailored to meet stringent safety and medical standards. We specialize in creating parts like industrial guards that adhere to safety regulations and medical-grade components like veterinary heating pads that meet health standards.

10. How do I choose the right thermoforming partner?

When selecting a thermoforming partner, consider their experience, material expertise, production capabilities, and ability to meet industry-specific requirements. At [Your Company Name], we offer comprehensive thermoforming services with a focus on quality, precision, and customer satisfaction.