Production

OmRajtech’s fiberglass production utilizes advanced techniques like RTM and FRP to create high-strength, lightweight composites. Our precision processes ensure consistent quality and superior mechanical properties for demanding industries.

Get a Free Quote

Why Partner with Us for Injection Molding?

Our adherence to ISO 9001:2015 standards ensures every phase of production, from tooling design to final quality assurance, follows stringent protocols. Detailed process evaluations and in-line quality checks guarantee parts meet exact dimensional and aesthetic requirements.

Equipped with versatile, multi-cavity presses (ranging from 110 to 1100 tons), we offer solutions including tool design, insert molding, sub-assembly, and kitting. Our technical expertise supports the development of high-precision tools and bank builds that transition seamlessly from prototype to full production.

Whether you need a limited run or mass production, our flexible process scales to meet your demand—from thousands to millions of units—without compromising quality or consistency.

Consistency and Quality

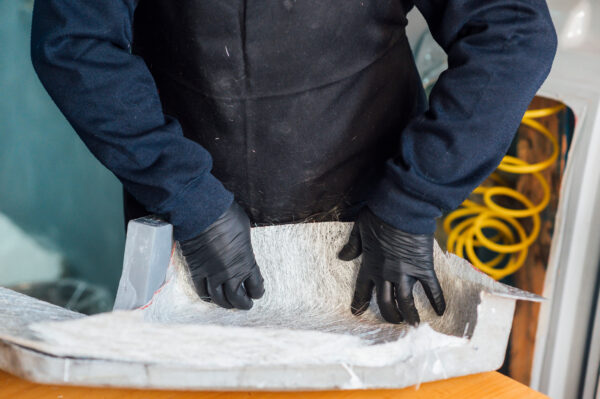

- Strict Material Testing: We thoroughly test all materials to ensure they meet the highest mechanical and chemical standards, guaranteeing optimal performance.

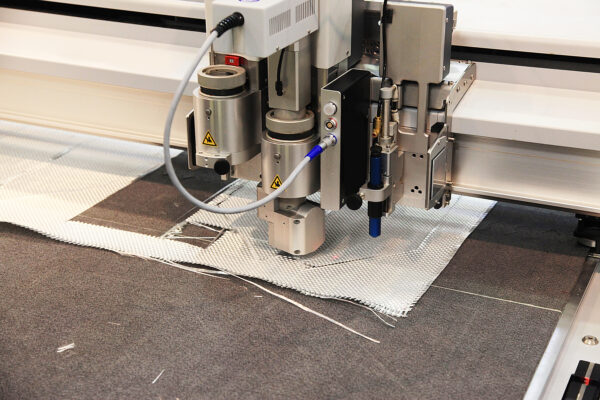

- Precision Manufacturing: Advanced techniques and high-precision processes ensure consistent fiber alignment and resin distribution for every part.

- Reliable Durability: Our commitment to quality and consistency results in fiberglass components that are durable, high-performing, and meet industry-specific standards.

Our Process in Action

- Advanced Molding Techniques: We use Resin Transfer Molding (RTM) and Fiberglass Reinforced Plastic (FRP) to create precise, high-strength composites tailored to specific customer needs.

- Rigorous Quality Control: Every stage of the production process is monitored, ensuring consistent resin distribution and fiber alignment for optimal durability and performance.

- Scalability and Precision: Our efficient production system is designed for both high-volume and high-precision manufacturing, ensuring consistent quality in every batch, regardless of scale.